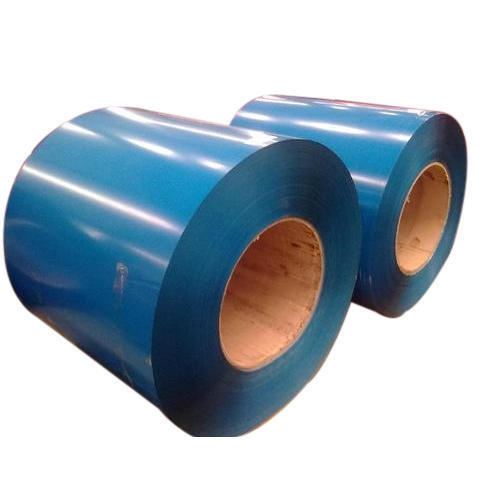

PPGI Coil

MOQ : 10 Tons

PPGI Coil Specification

- Surface Treatment

- Galvanized, Color coated

- Material

- Pre-painted Galvanized Steel

- Technique

- Cold Rolled

- Grade

- SGCC, DX51D, ASTM A653

- Coil Thickness

- 0.18 mm - 1.2 mm

- Coil Weight

- 3-10 metric tons

- Coil Length

- Customized, as per order

- Hardness

- Soft, Semi-hard, Full Hard

- Application

- Construction, Roofing, Cladding, Appliances

PPGI Coil Trade Information

- Minimum Order Quantity

- 10 Tons

- Supply Ability

- 50 Tons Per Week

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- North India

About PPGI Coil

The PPGI Coil is pre-painted galvanised iron. They find their usages in areas such as construction and automotive industries. They are efficiently manufactured using high grade galvanized iron in accordance with set industry standards. The PPGI Coil is also tested on diverse quality parameters in order to deliver finest quality range at client's end. Further they are known for their robust construction, high durability and seamless finish. They can be availed from us at reasonable price point.

"We are mainly dealing in North India"

Versatile Applications Across Industries

PPGI Coils are engineered to support a variety of uses, from roofing and cladding to high-end household appliances. Their robust structure and corrosion-resistant finish ensure a long service life in challenging environments. As a manufacturer, supplier, or distributor, you can trust the adaptability and consistency these coils deliver for both large and niche projects.

Customizable Features for Unique Requirements

Choose from a vast selection of colors matching the RAL palette or opt for custom shades to fit your particular design needs. The coils come in various grades, including SGCC and DX51D, and offer adjustable thickness and width. Customized coil length and edge type (mill/slit) help streamline your production processes.

Rigorously Tested for Quality and Compliance

Meeting international benchmarks like JIS G3312, EN 10169, and ASTM A755, each coil is produced through a stringent cold-rolled technique and detailed surface treatments. With a zinc coating range of 40-275 g/m and paint coatings meeting top industry standards, you are assured of reliable consistency and durability.

FAQs of PPGI Coil:

Q: How are PPGI coils typically processed and delivered for export?

A: PPGI coils are processed using a cold-rolled technique and subjected to strict quality controls. Each coil is packed in a standard export packageeither Eye to Sky or Eye to Wall orientationto ensure protection during transit. They are delivered according to international safety and shipping standards from trusted suppliers in India.Q: What advantages do pre-painted galvanized steel coils offer for construction and roofing?

A: Pre-painted galvanized steel coils provide exceptional corrosion resistance, vibrant and durable color finishes, and are lighter than traditional alternatives. Their ease of installation and low maintenance requirements make them highly beneficial for roofing, cladding, and construction applications.Q: When should I choose customized coil dimensions or colors?

A: Custom coil dimensions or colors are ideal when your project requires a specific aesthetic or when the structure design demands non-standard sizing. With options to tailor width, thickness, length, and color (including RAL palette and unique shades), these coils readily fit bespoke architectural or industrial needs.Q: Where are these PPGI coils commonly used?

A: These coils are widely utilized in construction (roofing and cladding), home appliances, and interior/exterior architectural features. Their strong, color-coated surfaces make them suitable for diverse environments and industry segments across India and globally.Q: What is the typical process for ordering PPGI coils from a supplier in India?

A: The process includes specifying your required standards, grade, dimensions, color, and packaging preferences. Once minimum order quantity (25 metric tons) is confirmed, production and export arrangements are made, ensuring compliance with your specifications and timely delivery.Q: How does zinc and paint coating thickness benefit my application?

A: A zinc coating of 40-275 g/m and top paint thickness of 15-25 microns ensure reliable protection against rust and weather, extending the products lifespan. A back coat (5-10 microns) adds additional resistance, making these coils suitable for demanding outdoor and indoor applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

" We are mainly dealing in North India"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS