Steel Angle

Price 44000.0 INR/ Ton

MOQ : 1 Ton

Steel Angle Specification

- Alloy

- Mild Steel

- Surface Treatment

- Galvanized

- Usage

- Construction and Fabrication

- Product Type

- Steel Angle

- Grade

- IS 2062

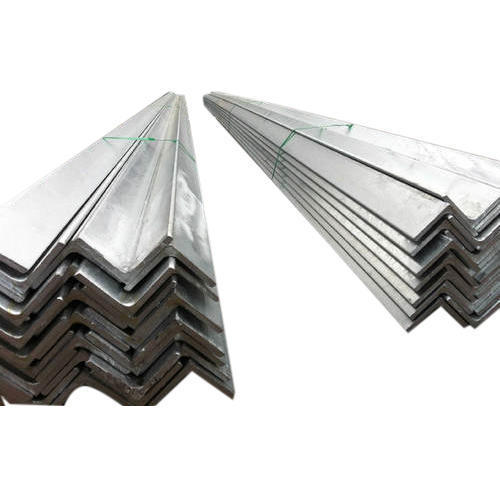

- Shape

- L Shape

- Thickness

- 3 mm to 12 mm

- Length

- Standard 6 Meter

- Width

- 20 mm to 100 mm

- Application

- Structural Support

- Color

- Silver

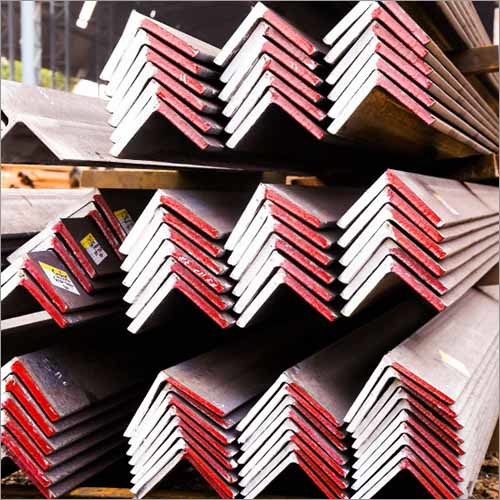

- Packaging Type

- Bundle Packing, Loose

- Tensile Strength

- 410 MPa (Min)

- Standards

- IS 808, IS 2062

- Customization

- Available

- Yield Strength

- 250 MPa (Min)

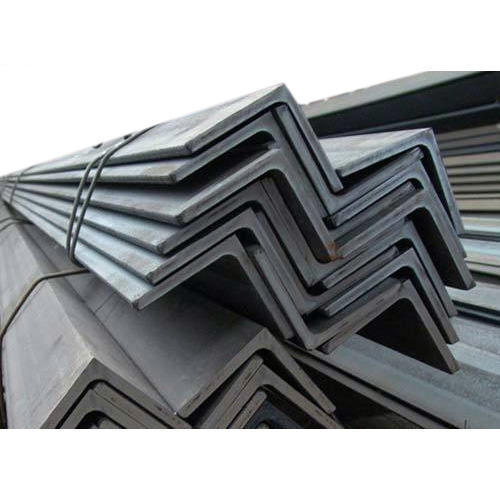

- Edge Type

- Sharp Cornered or Rounded

- Technique

- Hot Rolled

- Corrosion Resistance

- Yes

- Delivery Condition

- As Rolled or as Per Order

Steel Angle Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 10 Tons Per Day

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- North India

About Steel Angle

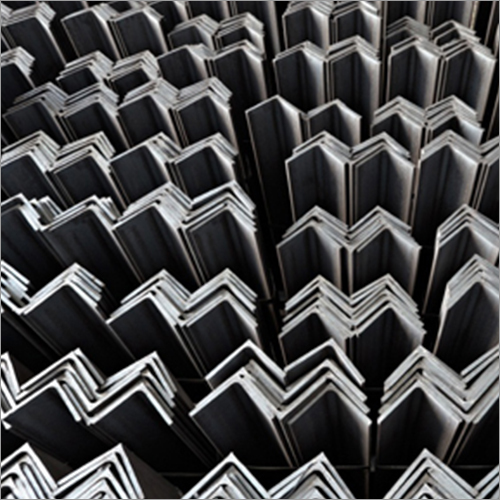

With a vision to be a pioneer in our domain, we are serving our respected clients by manufacturing and supplying excellent quality Steel Angle. It is fabricated at our state-of-the-art facility using premium grade stainless steel under guidance and supervision of adroit professionals. These angles are widely used in construction industries and various other sectors for grinding, welding, polishing and machining applications. Offered Steel Angle can be availed from us in different sizes and specifications as per requirements.

Features:

-

High mechanical strength

-

Durable and sturdy construction

-

Long service life

Versatile Steel Angles for Structural Support

Engineered for durability and strength, our Hot Rolled Steel Angles are optimally used in construction and fabrication industries. Thanks to the robust IS 2062 grade steel and galvanized surface treatment, these angles maintain their integrity even in demanding environments. With various thicknesses and lengths, they seamlessly integrate into diverse structural frameworks and support systems.

Delivery and Customization Options

We offer steel angles in bundle or loose packaging to accommodate your logistical requirements. You can choose from standard as rolled delivery or specify your processing preferences for additional customization. As a leading distributor, exporter, importer, manufacturer, service provider, supplier, and trader in India, we tailor solutions to meet unique structural specifications.

FAQs of Steel Angle:

Q: What are the standard sizes available for your hot rolled steel angles?

A: Our steel angles are offered in thicknesses ranging from 3 mm to 12 mm, widths between 20 mm to 100 mm, and a standard length of 6 meters. Custom dimensions are also available as per request.Q: How does galvanization enhance the performance of mild steel angles?

A: Galvanization applies a protective zinc coating to the steel, greatly enhancing its resistance to rust and corrosion. This treatment ensures durability and longevity, especially in outdoor or exposed structural applications.Q: Where can hot rolled steel angles be used?

A: These steel angles are widely utilized in construction and fabrication projects, including building frameworks, structural supports, bracing, and reinforcement of various structures due to their strength and versatility.Q: What is the process for customizing steel angles to project requirements?

A: Customization is available based on client specifications. Detailed requirements regarding size, thickness, edge type, or surface treatment can be communicated during the order process, ensuring tailored solutions for unique projects.Q: How are your steel angles packaged and delivered?

A: Steel angles are shipped either in bundle packs or loose, depending on customer preference. They can be delivered as rolled or processed as per order requirements, ensuring flexibility for diverse logistical needs.Q: What benefits do IS 2062 grade steel angles offer over other materials?

A: IS 2062 grade steel provides a combination of high tensile strength (minimum 410 MPa), reliable yield strength (minimum 250 MPa), and good weldability, making it ideal for structural applications that demand both strength and fabrication ease.Q: When should sharp-cornered versus rounded-cornered steel angles be used?

A: Sharp-cornered angles are typically preferred for precise, clean joints and aesthetic requirements, while rounded-cornered options are suitable when handling, safety, or additional stress relief is needed in the application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MS Angle Category

" We are mainly dealing in North India"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS